Stage systems.

Star Live has designed, engineered and delivered stages for the world’s biggest festivals, concerts and tours; our stages have hosted global artists for the last 45 years.

Our stage systems cater for events of all types:

- Titan™ – long-term installations

- Ultra Stage™ – the ultimate touring / stadia solution

- VerTech™ – the flagship festival favourite

With a proven history with the world’s biggest productions, Star Live is the premiere choice for stadia, tours and festivals.

The ultimate touring, stadium and festival stages.

Titan.

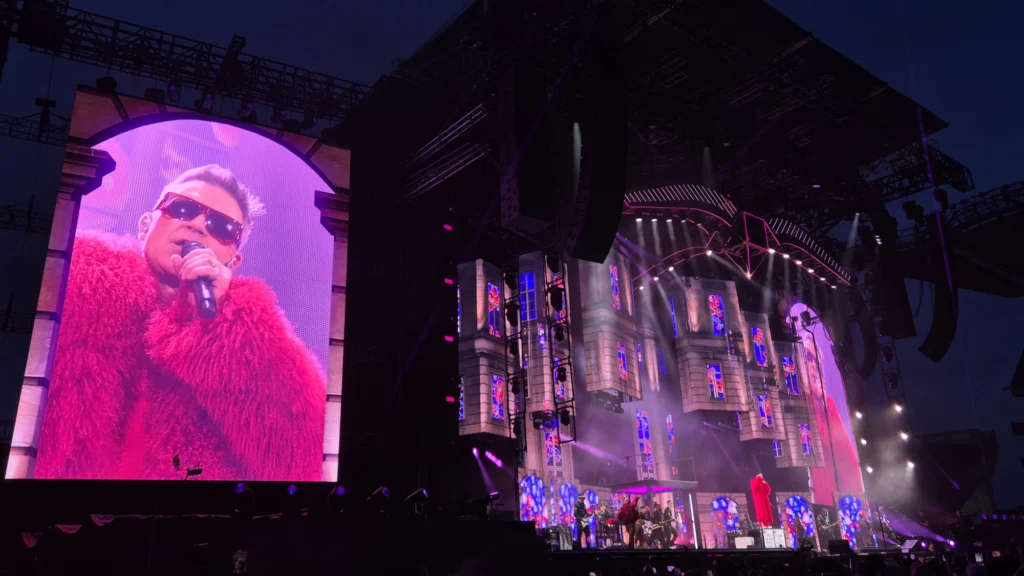

In 2022, Star Live introduced the Titan stage – our most advanced system for longer-term stage installations. Titan stages have played host to world-class artists, including Elton John, the Rolling Stones, Adele, Bruce Springsteen, and Pearl Jam, to name a few. From huge rigging loads to reduced working at height and manual handling, the Titan stage has a range of design features all tailored towards creating the ultimate production facility for the world's biggest artists and crews who need performance without limits.

Ultra.

The Ultra Stage is the new benchmark in stadium staging. The radical design opens up sightlines so much that killed seats can be turned into sold seats – enough to cover the entire cost of the stage per show. Designed to dominate even the largest stadiums and open fields, the all black Ultra Stage is engineered for ultra-fast builds and ultra-high rigging loads. Multiple identical systems and matching delay towers facilitate all tour itineraries. The enormous cantilevered roof above the performance area and the swept back wings are two of the iconic signatures that set this system apart.

VerTech.

Star Live VerTech event stages have a 35+ year proven history with the world’s biggest productions. The first VerTech stage was built in 1990 for the infamous Stone Roses gig on Spike Island. Now widely considered the premiere choice for entertainment venues, the 'versatile technology' allows for multiple configurations, performance widths, canopy depths and trims. Fixed length towers within the stage substructure allow construction into terraces, maximising audience capacity and sightlines.

Bespoke stage designs.

Star Live regularly creates bespoke staging solutions. From custom-made stages in front of Buckingham Palace for The Queen’s Platinum Jubilee celebrations and the patriotic platform for the King’s Coronation Concert, through to the Hangar Stage with almost unlimited rigging capacity at Parklife festival, there is no stage design brief we cannot meet.

Technology support structures.

Our vast range of modular components and rigging equipment can be integrated to make structures for almost any conceivable event requirements. We regularly build structures that can support loads from 0.5 to over 100 tons and are often only constrained by the size of the stadiums and arenas we work in. Our designers focus on designing out Work at Height and picking sizes that optimise transport and handling. There is no equipment used at events that we have been unable to find a way to support where it is required.

The value in our build approach.

Speed.

Rapid build cycles and streamlined logistics compress on-site time, keeping festival and stadium schedules tight without compromising complexity or quality.

Scale.

Performance widths up to 30m, trim heights in excess of 20m, and rigging capacities of 100+ tons.

Production-Ready.

Huge rigging capacity for sounds and light; Star Live systems are designed to be production-friendly.

Touring.

Multiple identical systems and components designed for efficient trucking and container shipping.

Weatherproof.

Durable membranes and class-leading wind management keep the structure secure in extreme conditions.

Sightlines.

With multiple wing widths, positions and angles available, stage designs can be optimised to deliver maximum sightlines and ticket inventories.

Ready to transform your next project?

We’re ready to help you create innovative, adaptable spaces that deliver exceptional commercial value.

Frequently asked questions.

How quickly can Star Live deploy a staging system?

Deployment timelines vary depending on the system and scale of the project. VerTech and Ultra are designed for rapid build and de-rig, making them ideal for touring and time-sensitive schedules. Titan, while requiring a longer installation period, is better suited for large-scale projects where the structure remains in place for an extended duration.

Whatever the setup, we work closely with your production schedule to ensure efficient delivery, with modular systems engineered to minimise time on site.

Can your stage systems be used for both indoor and outdoor events?

Yes, all our staging systems are designed for versatility. Whilst our weatherproof systems like VerTech and Titan are ideal for outdoor environments; they are equally effective for indoor arenas and venues and ground support systems with or without canopies. We can modify configurations and installation methodology to suit specific indoor requirements including venue height restrictions, access and floor loading to provide a focal point for your event or simply additional rigging capacity.

What weather conditions can your stages withstand?

Our staging systems are designed to withstand challenging weather conditions, with standard configurations engineered for wind speeds up to 25m/sec (56mph). Our weatherproof membranes provide protection against heavy rain, and our structures are designed with proper drainage systems.

Technical specifications.

What are the maximum dimensions available for your stage systems?

- VerTech™: Performance widths of 15m, 20m, and 25m with variable canopy depths

- Titan™: Configurable widths up to 30m

- Ultra Stage™: Custom configurations up to 25m

- All systems available with variable trim from 8m-15m with VerTech™, and up to 20m with Titan™ and Ultra Stage™

What rigging capacities do your stage systems offer?

-

VerTech: starting at 30,000kg UDL scalable to over 60,000kg with multispan™ technology

-

Titan: up to 100,000kg UDL

-

Ultra: Near-unlimited capacity for complex productions, with previous installations supporting over 100 tonnes

Do you provide stage systems that comply with international safety standards?

Yes, all our stage systems comply with international safety standards and regulations. We provide comprehensive documentation including structural calculations, wind loading certifications, and material specifications. Our global experience ensures we can meet region-specific requirements.

Logistics and operations.

How much space is required around the stage for construction?

We typically require a working area extending approximately 5-10m beyond the stage footprint, depending on the system. This space accommodates construction equipment, stage system, and safe working practices. Our team can work with limited space constraints by adapting our build methodology.

Can your stage systems be customised with branding elements?

Absolutely. All our stage systems can incorporate custom branding elements including scrims, banners, LED screens, and projection surfaces. We work with your creative team to integrate branding elements that maintain structural integrity and safety.

What site conditions are required for your stage systems?

Our stages can be installed on various terrain types, though we generally require a site survey and topographical detail, and confirmation of ground bearing capacity. For uneven terrain, stadium terraces or where other site obstructions exist, we have a range of levelling solutions. We conduct thorough site assessments to identify specific requirements for each installation.

Project planning and support.

What technical information do you provide for production planning?

- Detailed 2D CAD drawings and 3D visualisations

- Technical specifications for design and integration with lighting, sound and video

- Load calculations for show rigging plots

- Show specific structural calculations where required

Do you provide onsite technical support during the event?

Where necessary our team remain on site for the duration of your event to provide technical support and implementation of wind management procedures when required.

How do you handle international projects and logistical challenges?

With extensive global experience, we expertly manage international logistics including shipping, customs clearance and local labour coordination. Our systems are designed for efficient transport with many components packaged for international transit and material handling systems, and we maintain strategic equipment depots — including fully operational stage systems in the Middle East, where we also have a regional base. This approach reduces shipping costs, shortens lead times, and helps lower the overall carbon footprint of your project.