Design & Build.

For developers, architects, landowners and venue operators facing pressure to deliver high-performance or meanwhile-use spaces more efficiently, Star Live offers building solutions that bridge the gap between temporary and permanent construction.

Our approach combines rapid deployment capabilities with sustainable designs, enabling venues to evolve with changing requirements while meeting permanent building standards.

This creates opportunities to accelerate development timelines, phase investments strategically, and deliver environmentally responsible entertainment and sporting venues with reduced material waste and lower carbon footprints.

Fast-track, innovative construction.

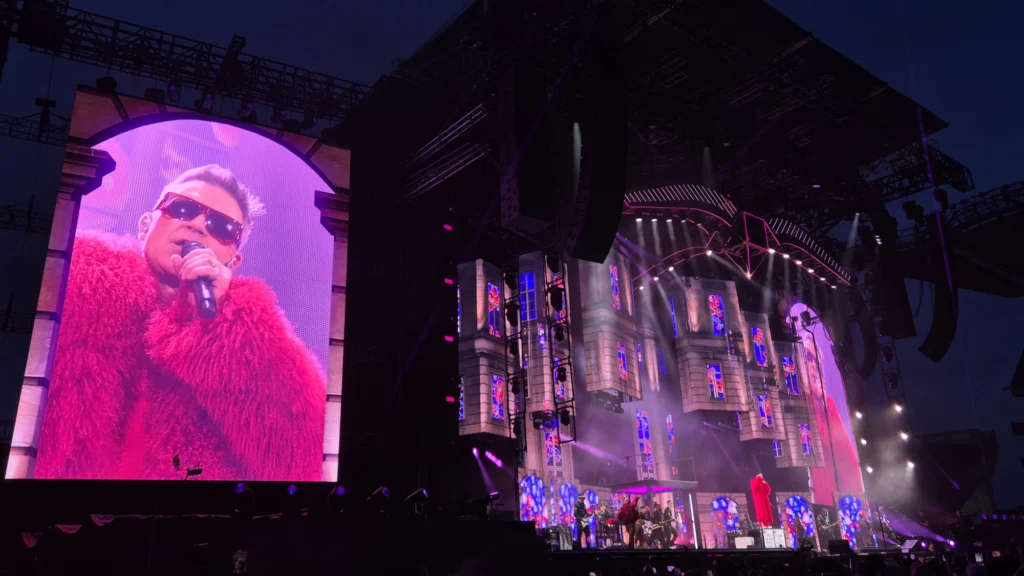

Exhibition & showcase structures.

Architecturally striking, high-profile environments for exhibitions, expos, launches and brand statements – built for visibility, scale and standout presence on the global stage.

Public sector infrastructure.

Robust, regulation-compliant buildings for defence, education, healthcare and emergency response — including military facilities, temporary schools, welfare units and government support hubs.

Industrial & logistics buildings.

Durable, flexible, relocatable structures for warehousing, transport, utilities or workspace use — designed for operational efficiency and long-term performance in demanding environments.

Sports & team facilities.

Adaptable structures for training, matchday and team operations – from modular stadium builds and warm-up zones to changing areas, gyms and back-of-house support.

Retail, commercial & hospitality venues.

Versatile, branded environments including showrooms, ticketing spaces, F&B outlets and premium hospitality suites – built for flexibility, access and guest experience.

Workspaces & operational hubs.

Fully serviced office and support spaces for semi-permanent or permanent use – including site HQs, press centres, studios and production control facilities.

The value in our build approach.

Off-site manufacturing.

Factory-controlled production delivers consistent quality with precise tolerance control.

Structural innovation.

High load-bearing capacity with minimal ground preparation requirements.

Compliance & certification.

Fully insulated systems meeting all demanding building control and sustainability specifications.

Integration expertise.

Seamless incorporation of MEP services, branding elements and specialised requirements.

Fast deployment.

Pre-engineered systems and streamlined logistics accelerating on-site delivery to unlock revenue streams earlier.

Lifecycle flexibility.

Structures designed for relocation, adaptation or long-term use, supporting evolving needs over time.

Ready to transform your next project?

We’re ready to help you create innovative, adaptable spaces that deliver exceptional commercial value.

Frequently asked questions.

How does your construction approach differ from traditional methods?

Our method combines the precision of off-site manufacturing with the speed of rapid on-site assembly, reducing construction schedules by 40–60%. By applying engineering principles from large-scale event structures, we deliver high-performance buildings that meet permanent standards – faster, more flexibly, and with less disruption.

What types of projects are best suited to your modular approach?

Our solutions excel for entertainment venues, sports facilities, exhibition spaces, and commercial environments where speed to market, future adaptability, and quality are paramount. They’re particularly effective for phased developments, sites with constrained access, or projects requiring future relocation potential.

Can your structures meet the same standards as traditional construction?

Absolutely. Our buildings fully comply with UK Building Regulations for permanent use, delivering excellent thermal, acoustic, and structural performance. For example, the NEON project at Battersea Power Station features roof panels delivering a U-value of 0.18 W/m²K—meeting demanding environmental and regulatory compliance requirements.

How sustainable is your construction approach?

Our approach significantly reduces material waste through factory precision manufacturing. With demountable designs enabling up to 95% material recovery, we cut embodied carbon and align with ESG goals, enhancing sustainability credentials and improving whole-life environmental performance.

What are the cost implications compared to traditional construction?

While initial manufacturing costs may be comparable to traditional methods, our approach delivers major savings over the project lifecycle. Faster programmes reduce preliminaries and overheads, limit exposure to weather delays, and unlock revenue sooner. Structures designed for re-use or relocation further improve whole-life value.

How quickly can you deploy a typical project?

Timelines vary based on project complexity, but our approach typically delivers 40-60% faster than traditional methods. For example, a 3,000m² venue that might take 9-12 months using conventional methods could be operational in just 4-5 months using our systems.

Do you offer design services or work with external architects?

Yes. We regularly collaborate with architects and design consultants to help bring bold, creative visions to life through our modular and semi-permanent systems. Our in-house engineering team provides the technical insight needed to assess feasibility, adapt conventional designs for modular construction, and models lifecycle performance.

Whether we’re advising on early-stage concepts or delivering full design and build packages, we offer the practical insight needed to turn ambitious ideas into deliverable, scalable solutions.

What ongoing support do you provide after project completion?

We offer complete documentation packages and technical support throughout your building’s lifecycle. For structures designed for relocation or reconfiguration, we provide expert assistance with dismantling, transportation, and reassembly to ensure optimal performance at each deployment.